Overview

The ECO (Engineering Change Order) Master page starts with a ‘List View’ feature.

-

On this page, you will see all records related to this function.

-

By clicking on the New ECO Master Header, you will be brought to the page to create a new Engineering Change Order (ECO).

The decision to use Engineering Change Orders is made at the Division Master Level.

-

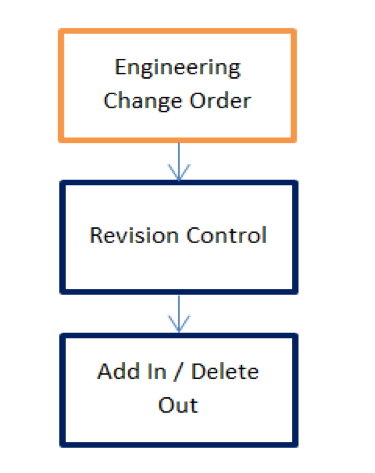

If activated, the Engineering Change Order becomes the mechanism by which engineering changes are submitted, approved, and implemented.

-

When a change to a product configuration is required, an ECO and an Item assigned to the ECO are required to control the process.

-

The Engineering Change Control affects both the Bill of Materials and Routings.

NOTE If activated, all engineering-related activities in that Division are under ECO Control, and Revisions will require an Engineering Change Order as a prerequisite.

NOTE If activated, all engineering-related activities in that Division are under ECO Control, and Revisions will require an Engineering Change Order as a prerequisite.

The Engineering Change Order is status-controlled to manage the flow through the Engineering Change Order Process.

Under ECO control, item revisions cannot be entered and implemented without an ECO. The ECO status determines the item revision status.

-

When the ECO is at the Pending or Released status, the item revisions assigned to the ECO are at the ECO status.

-

When the ECO status is changed to implemented, the revision status of the items assigned to the ECO is also changed to implemented.

The Engineering Change Order is flagged with the following status-related dates:

-

Date Approved: The date the Engineering Change Order is Approved ('Approval Status' was changed to 'Approved').

-

Date Released: The date the 'ECO Status' was changed to 'Released'.

-

Date Implemented: The date the 'ECO Status' was changed to 'Implemented'.

The ECO No field is system-generated. Enter each field following field help guidance and drop-down options.

NOTE Some fields may have a prerequisite entry (for example, ECO Reason).

NOTE Some fields may have a prerequisite entry (for example, ECO Reason).

Navigation

ECO Master

Processing

Step 1 – ECO Header

-

The ‘header’ of this record is generic in that it is not linked to any specific part number or numbers.

-

Once the header page is entered and saved, an ECO Detail Tab will display.

-

On the ECO Details tab, select the ‘Add ECO Details’.

NOTE You can also enter Notes and Attach files from this page.

NOTE You can also enter Notes and Attach files from this page.

Step 2 - ECO Details

Clicking ‘Add ECO Details’ brings the user to a new page.

NOTE An incremental Revision Number is created unless the Division is set for alpha-numeric revisions. In that case, the user will manually enter the correct Revision.

NOTE An incremental Revision Number is created unless the Division is set for alpha-numeric revisions. In that case, the user will manually enter the correct Revision.

EXAMPLE Various ECO and ER Configurations

EXAMPLE Various ECO and ER Configurations

Create a Change to a Bill of Material or Routing with ECO Control Active and Revision Control Active

-

Create a new ECO

-

Use the ECO Detail Tab to create the related Revision

-

Manage ECO and Revision

-

The Revision Status cannot be changed to Implemented until the ECO status is changed to Implemented.

-

If the ECO Status is changed to Implemented, then all Revisions attached to the ECO also become ‘Implemented’.

-

The 'Effective Date' of the ECO Detail will set the 'Start Date' of the related Revision, 'Add Date' or 'Delete Date' of the related Engineering BOM Master, and 'Add Date' or 'Delete Date' of the related Routing Operation.

-

Only Revisions with a Status of Implemented will affect MRP and Cost.

-

Use the Revision to modify the Bill of Material or Routing based on the Revision Start Date and Add Effectivity Control.

Create a Change to a Bill of Material or Routing with NO ECO Control and Revision Control Active

-

On the Engineering Item Master, use the Revision Tab to create a new revision.

-

Manage Revision - The Revision Status must be ‘Implemented’ for the Revision to affect MRP or Cost Roll Up.

-

Use the Revision to modify the Bill of Material or Routing based on Revision Start Date and Add / Delete Effectivity Control. Make the Bill of Material or Routing changes first, then Implement the Revision.

Create a Change to a Bill of Material or routing with No ECO Control and No Revision Control

-

Navigate directly to Bill of Material or Routing and add/delete a component or operation. Use the Add / Delete Effectivity control to determine when the component or operation is in effect.

Engineering Revision (Edit)

Use the Engineering Revision (Edit) page to view or edit existing Revisions.

-

If ECO is active, Revision Control is also active, and new Revisions are created through the ECO process.

-

If Revision control is active, but ECO is not active, then new Revisions can be added using the Engineering Item Master object.

-

If neither ECO nor Revision control is active, then Revisions other than the initial Rev 000000 are for reference only, if used, and are not used as controls in Rootstock.

SEE ALSO

ECO Master: Application and Terminology

Inventory Item Master

Engineering Item Master