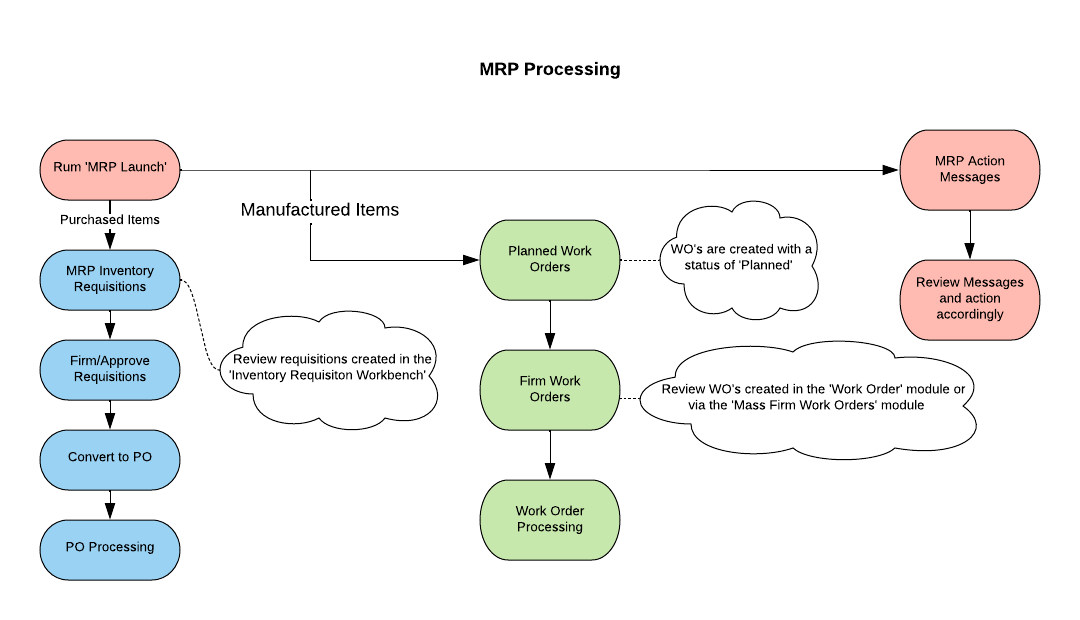

Overview

The MRP logic for an item presents the demand orders, the supply orders and projected inventory. The logic compares an item’s demand order date to the item’s supply order date. If there are no existing orders to meet the demand requirement, a planned order is generated. If the existing supply order date (Status 2 or greater) is other than the demand order date a Reschedule (Action) exception message is generated. Reschedule ( Action) messages are generated only when the supply order has the following characteristics. If the item is manufactured, the status of the work order must be “2” or greater. If the item is purchased, the status of the Requisition must be “2” or greater. Note: A Purchase Order may also be a candidate for a reschedule message, which is always at status 2 or greater.

MRP Output - Planned Work Orders and MRP Planned Inventory Requisitions

The MRP Requirements function generates a list of all individual requirements by item number.

Data includes item quantity, required date, parent item, order number and status. Along with the requirements, MRP calculates Planned Inventory Requisitions and Planned Work Orders.

MRP Output Reschedule (AKA-Action Message)

These are the reschedule messages that are created for each MRP run. MRP in its planning logic will assume that supplies can be ‘rescheduled’ to meet demand and then with the ‘rescheduling’ of the supplies to meet demand having been done and assuming that there is no excess supply, MRP will add the planned supplies (e.g. inventory requisitions and work orders) to satisfy the remaining demand that is not addressed by the ‘rescheduling’ of a supply. The creation of these MRP reschedule message records are really just a mathematical consideration of how to ‘reschedule’ which quantities of a supply to meet the demands. There can be multiple reschedule messages for a given supply.

The user looking at these reschedule messages, in combination with a number of other variables, (such as is this a requisition, or a purchase order or a work order), will decide the appropriate action to take. The reschedule messages are intended to be a ‘guide’ where a user’s own experience would use this as one source of input as to the real action that should be taken.

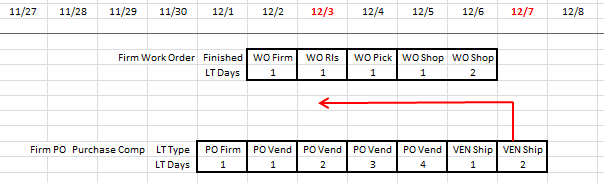

NOTE MRP Planning will generate a ‘Reschedule In” Action Message indicating that the Purchase Order be rescheduled In from 7 Dec to 3 Dec in order to meet the demand from the Work Order.

NOTE MRP Planning will generate a ‘Reschedule In” Action Message indicating that the Purchase Order be rescheduled In from 7 Dec to 3 Dec in order to meet the demand from the Work Order.

SEE ALSO

MRP Overview

MRP Application

MRP Terminology

MRP Planning Policies and Quantities

MRP Lead Times

MRP Action Message Search

MRP Mass Firm

MRP / DRP Net Change

MRP Primary Record Types

MRP Launch

MRP Scheduling (Automate MRP Processing)