Overview

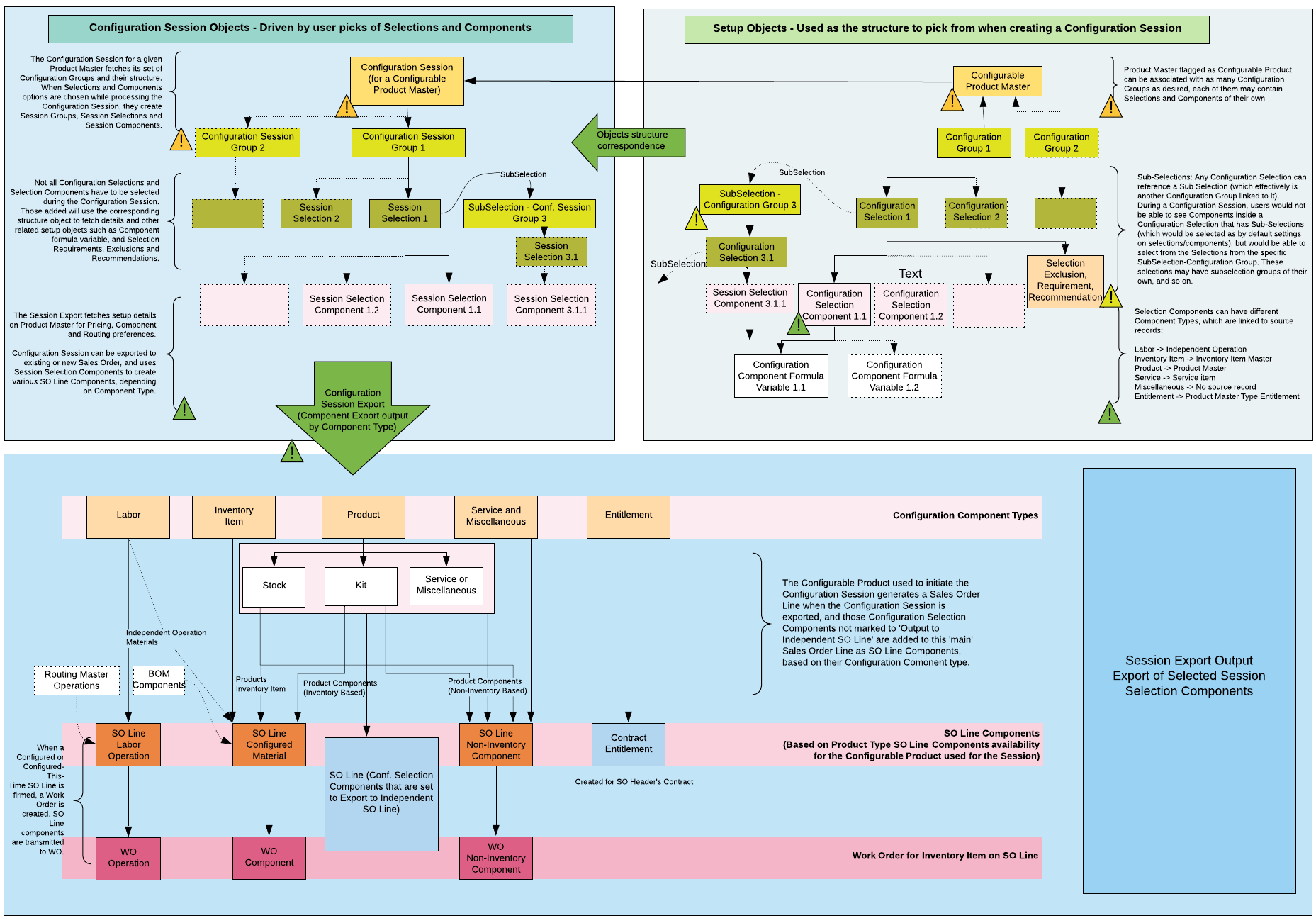

Rootstock‘s Product Configurator allows users to set up configurations that can be applied to “configurable” Rootstock Products allowing the selection of options applicable to a given product configuration. The Product Configurator can be launched from a Sales Order or Rootstock Quote to create an order line, or can be executed “stand-alone” and, if desired, exported to a Sales Order or Rootstock Quote.

The export of a Configuration Session would include not only the creation of Sales Order Header/Line but also of those selections of options made during the Configuration Session, transferred as Sales Order Line Components (either Non-Inventory, Material or Labor) to said Sales Order Line.

NavigationProduct Configurator

ApplicationProduct Configurator functionality in Rootstock can manage key functions such as:

- Ability to pre-define Configuration Group structures, with optional, mandatory and/or dependent Selections, which can contain Components. These components may reference entities of different type/nature such as Independent Operations, Inventory Items, Products, Service Items, or simply be miscellaneous without a source object reference.

- Ability to create Configuration Sessions and select from those pre-defined structures, on a Session to Session basis.

- Ability to export Configuration Session details to a Sales Order. This can potentially generate Work Orders with Work Order Components and Operations derived from the Configuration Session.

- Ability to create one or more Sales Order Lines as part of the Configuration Session export, all within the same Sales Order Header.

The Product Configurator supports:

- Price Discount Logic

- Min/Max and Decimal Quantity Validation for Configuration Selections.

- Sub Configuration Groups, assigned to Selections so that the configuration structure can be designed to have multiple levels of Groups & Selections within a given 'Main' Configuration Group.

- Up to three Pricing Methods for Configuration Selection Components, based on the Component Type.

- Linkage of Material to Operation Numbers, used for First-Operation Work Order Backflushing.

- Assigning Transaction User to Labor Operations, used for Labor Backflush.

- Use of Formulas to calculate a Component's Qty Per and Price values, based on other entities included in the Configuration Session, defined as Formula Variables.

- Configuration Session Pricing and two alternate price options which are carried over to the Sales Order Line, as a reference, when a Configuration Session is exported. These can be configured and labeled on a Customer to Customer basis.

- Customer-Product specific Product Configurator structures.

- Component Quantities with up to six decimals precision and three different methods as value rounding options.

Product Configurator Article - Table of Contents

Product Configurator Article - Table of Contents

- Context Articles

- Product Configurator - Terminology

- Product Configurator Setup

- Setup Objects - Building Product Configurator Structures

- Configuration Group

- Configuration Selection

- Configuration Selection: Exclusions, Requirements & Recommendations

- Configuration Selection: Price Adjusting Selections

- Configuration Selection Component

- Source Objects for Creating Configuration Selection Components

- Products

- Service Items

- Independent Operations

- Inventory Item Master

- Configuration Selection Component: Second Selection

- Configuration Selection Component: Formula Variables

- Configuration Selection Component: Feature Detail

- Configuration Selection Component: Price Methods and Cost Sources

- Configuration Session Processing

- Configuration Session

- Exporting Configuration Session To Sales Order

- Configuration Session Export: SO Line Component Output by Configuration Component Type

SEE ALSO

Rootstock Schema Builder - Product Configurator

Sales Orders Entry - Overview

How to store Images on the Salesforce Platform