Overview

This initiates the Work Order Scheduling function for selected Work Orders.

The Work Order Scheduling Function provides two controls for Firmed (status) Work Orders:

1. Extract Work Order Operations

The Work Order Scheduling Function can be used to extract operations for a single Work Order, or multiple Work Orders. Extracting Work Order Operations creates an Operation by Operation Schedule based on the Routing for the item being manufactured. Each Work Order Operation is established with a Start Date, Completion Date, Number of Hours Required and Work Center Required. The Operation Scheduling Calculations use the routing data which includes Operations, Operation Types, Work Centers, Operation Standards and Scheduling Type (labor or machine) in creating the Operation by Operation Schedule.

The Extract Operation function creates operation schedules using the Work Order Pick Date as the start date of the first operation under most circumstances. The Pick Date of a Work Order is determined by the Manufacturing Lead Time for the Item and the Due Date of the Work Order.

There is one situation where the Work Order Scheduled Release Date is used as the Start Date of the first operation. If the first operation is a ‘Labor Only’ operation, then the Work Order Scheduled Release Date is used as the scheduled start date of the first operation.

Work Order Due Date – Manufacturing Lead Time = Start Date of First Operation.

2. Determine Work Order Operation Priorities

The Scheduling Function calculates a priority code for each Work Order Operation using a critical ratio method. The Work Center dispatch listing then displays Work Order Operations in priority code sequence.

NOTE The Scheduling Function provides the means to calculate operation priorities for all operations for one or more Work Orders simultaneously. The User may choose to set the priority for any one individual operation from the operation itself.

NOTE The Scheduling Function provides the means to calculate operation priorities for all operations for one or more Work Orders simultaneously. The User may choose to set the priority for any one individual operation from the operation itself.

Forward Scheduling/Back Scheduling

Division Master > Shop Floor Control

Field

Reset WO Release Date After Op Extract: When checked all scheduling will be Back Scheduling. When unchecked all scheduling will be Forward Scheduling and individual Work Orders can be selected for Back Scheduling.

Navigation

Work Order Scheduling

Fields

Division: The Work Order Scheduling Function supports scheduling by Division. However, the process can only be run for the current Division associated with the User. To run for a different Division, the User must first change his or her current Division, either using the pop out Quick Menu, or by changing the Current Division on the Rootstock Manufacturing User Record.

Run Options: Before starting the process a Run Option must be selected.

|

Run Option

|

Description

|

|

Schedule – Extract Operations if Necessary

|

Displays all open Work Orders with a minimum status of 2 (Firm). Select the Work Order to have the Scheduling Function extract operations, establish a priority for the operations and to populate the Dispatch Report.

|

|

Extract Only

|

Displays only Work Orders where the operations have not yet been extracted. Select the Work Order(s) to have their Operations extracted.

|

|

Schedule Only

|

Displays all open Work Orders with a minimum status of 2 (Firm). Select the Work Order(s) to have the Scheduling function establish a priority for the Operations and to populate the Dispatch Report.

|

Display Work Orders (Button): Based on the Run Option selected, the Display Work Order selection will present the User with a list of applicable Work Orders. The orders presented to the user for selection are all the orders that have a Work Order status of 2 through 7 (Firm through Not Closed).

Work Order Selection

1. Selects the Work Order(s) for which the Run Option is to be applied. Previously scheduled orders can be re-scheduled. If a Work Order is selected to be scheduled, then all operations which have not yet been completed on the Work Order are scheduled.

2. Select the Process button to launch the task. A confirmation that the scheduling has been completed will be displayed on the screen when the process completes.

Processing

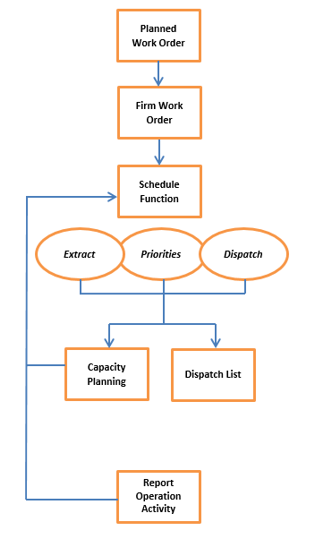

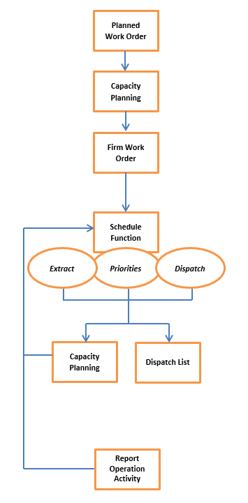

Scheduling and Capacity Planning can occur either before Work Order firming is done, or after Work Order firming is done, depending on which option is the best fit for the specific organization.

Both options are valid and neither option is restrictive of the other. For any group of MRP Planned Orders there may be a subset of items where the MRP plan is sufficient –

- Option 1 - Analysis after Firming: For these items the Firming and Scheduling of the Work Order comes first, capacity impact analysis second. For a different subset of planned orders the analysis must come first.

- Option 2 - Analysis before Firming: For these items, the Firming and Scheduling of the Work Order is done after the analysis of key Work Center Conditions.

The two options are outlined below.

More detail is shown in the Capacity Planning section.

Option 1 - Analyze After Firming Work Orders

- Firm the MRP planned Work Order.

- MRP Planned Orders do not have operations extracted.

- MRP does not plan Work Orders under any capacity restraint.

- Run the Schedule Process after Firming.

- Extracts Operations (operation schedule created).

- Establishes Operation priorities.

- Updates the Dispatch Report.

- Analyze the impact of the Work Order Operation Schedule on key Work Centers from a load/capacity standpoint.

- Make changes where necessary.

- Run the Schedule Process after making the changes (Reschedule).

- Update operation priorities and the Dispatch Report.

Use Case

Under this process, MRP determines the best quantity and date for the order. The Work Order is then changed to status Firm, the operations are extracted (operation schedule created), and a priority is established. Work Centers are then analyzed for any overload conditions. Conditions can then be managed via overtime, shifting of resources, etc., but the Work Order is not necessarily rescheduled.

Analyze After Firm Process

- MRP creates planned Work Orders based on demand and lead time. MRP does not plan under any capacity restraints.

- Use the Work Order Mass Firm Function and/or Work Order edit to change the Work Order status from Planned to Firm.

- Work Orders must be at a minimum Status Firm to use the Scheduling Function.

- Use the Scheduling Function to Extract Work Order Operations (create Operation Schedules), establish Operation Priorities and populate the Dispatch Report.

- Work Orders must have the operations extracted for use within the Capacity Planning Function.

- Use the Capacity Planning Function to monitor and manage load conditions by Work Center, Work Order, Project or Company Overview (all Work Centers). After changes to Work Orders or Work Order operations, use the Scheduling Function to update Priorities and the Dispatch List.

- Use the Dispatch List Function to identify the Work Load by Work Center /Operation / Work Order / Date / Priority.

- As Work Order operations are completed (Quantity Booking), the Demand (load) against the operation is reduced. This activity updates the load balances in both Capacity Planning and Dispatch Report.

Option 2 - Analyze Before Firm

- For any MRP planned Work Order:

- Analyze the condition of key Work Centers to determine the availability of resources.

- MRP Planned Orders do not have operations extracted (operations scheduled).

- MRP does not plan Work Orders under any capacity restraint.

- Firm the MRP Planned Work Order with a date based on Capacity Analysis.

- Schedule the Work Order.

- Extract Operations (Operation Schedule created).

- Establish Operation priorities.

- Update the Dispatch Report.

Use Case

Under this process, MRP determines the best quantity and date for an order. The planned Work Order Date may conflict with other Work Orders scheduled for the same time and competing for the same resource. From a strategic standpoint, the company cannot chase demand by adding resources to an overloaded Work Center because capacity is fixed. Under this process, capacity is analyzed first where the user determines the availability of the resource and schedules the Work Order accordingly (change due date, change the status to Firm).

Analyze Before Firm Process

Analyze Before Firm Process

- MRP creates Planned Work Orders based on demand and lead time. MRP does not plan under any capacity restraints.

- Analyze the condition of key Work Centers to determine the availability of resources.

- Based on resource availability, establish a date (change status to Firm) for the Work Order. Use the Work Order Mass Firm Function and/or Work Order edit to change the Work Order Status from Planned to Firm.

- Work Orders must be at a minimum Status Firm for use within the Scheduling Function.

- Use the Scheduling Function to Extract Work Order Operations (create operation schedules), Establish Operation Priorities and populate the Dispatch Report.

- Work Orders must be at a minimum Status Firm for use within the Scheduling Functions.

- Work Orders must have the operations extracted for use within the Capacity Planning Function

- Use the Capacity Planning Function to monitor conditions by Work Center, Work Order, Project or Company Overview (all Work Centers). After changes to Work Orders or Work Order operations, use the Scheduling Function to update Priorities and the Dispatch List.

- Use the Dispatch List Function to identify the Work Load by Work Center / Operation / Work Order / Date / Priority.

- As Work Order Operations are completed (Quantity Booking) the Demand (Load) against the operation is reduced.

SEE ALSO